News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

What are the technical measures to improve the service life of magnesium anode?

- Author:Libo

- Source:wamericanfreedomlawncare.com

- Date:2021-06-11

- Click:0

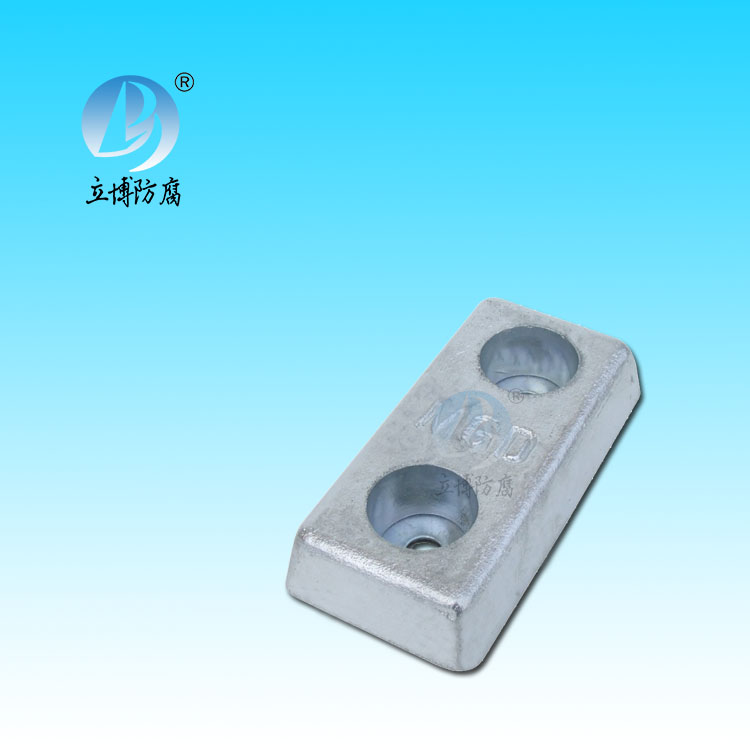

Magnesium is a active metal element, the standard electrode potential is negative, and the absolute value is very large, resulting in the corrosion resistance of magnesium and magnesium anode is very poor, which hinds magnesium anode products in the use of advantages, limited its application range.

The direct cause of magnesium anodic corrosion is the introduction of alloying elements and impurity elements which lead to the occurrence of a second phase in magnesium anodic corrosion. The corrosion forms of magnesium anodes are: galvanic corrosion, pitting corrosion, stress corrosion cracking, intergranular corrosion, filamentous corrosion and high temperature oxidation. The electrochemical corrosion of magnesium anode is related to the pH value of the solution, the properties of the solution, the composition of the alloy and the environment.

In order to improve the service life of magnesium anode materials, metallurgical factors should be controlled to improve the corrosion resistance of magnesium anode materials, including alloying elements, impurity elements, phase composition and microstructure. The research of surface treatment technology, such as chemical transformation treatment of magnesium anode, anodic oxidation, plasma micro-arc anodic oxidation, metal coating and physical vapor deposition coating technology, brings new vitality to improve the corrosion resistance of magnesium anode by plasma technology.

In order to improve the corrosion resistance of magnesium anode, a new process of ion injection, laser annealing and rapid solidification has been used, which is characterized by forming a layer of uniform and amorphous surface structure film on the metal surface.

Of the magnesium anode by high frequency induction surface alloying treatment results satisfactory, through to the ZM5 magnesium anode samples in 4 okh: high frequency induction furnace air cooling to room temperature after heating treatment, compared with the samples without induction treatment, greatly improve its corrosion resistance, the change of the surface phase structure organization can effectively inhibit the corrosion of magnesium anode.

Micro-arc oxidation technology is another new metal surface treatment technology, its principle is to place the material in electrolyte solution, using the role of high current and high voltage, on the surface of the matrix metal to generate a matrix metal oxide ceramic layer, and dense without defects, in order to improve the corrosion resistance of the metal. Experiments on MB8 magnesium anode show that the thickness of mgO ceramic layer has little effect on the improvement of corrosion resistance, and the corrosion resistance of amorphous mgo ceramic layer is better than that of crystalline mgo ceramic layer.

客服QQ

客服QQ