PRODUNT

Magnesium alloy CP

Aluminum alloy CP

Zinc alloy CP

Reference electrode

Test Stub

Thermite flux

Power impressed anode

Auxiliary materials

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Ignition gun

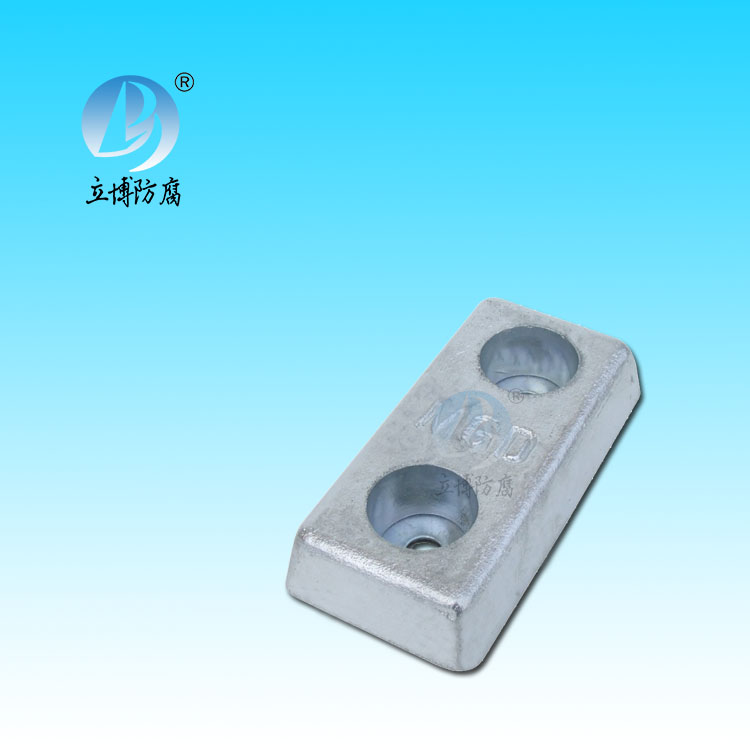

Type:Thermite flux

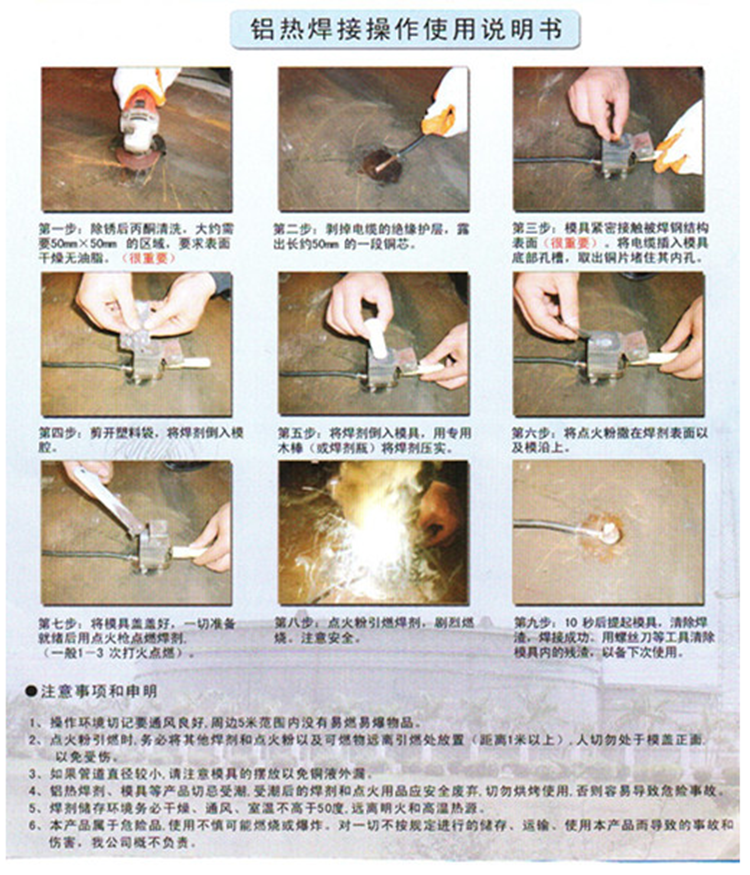

Features:The welding process simple operation, does not require an external power source and heat source, and the welding of low cost, stable and reliable quality, very suitable for field welding operation of cable and other metal components, this manual involves the product is suitable for the cathodic protection system installation in the process of copper core cable and connection of steel structure welding or copper cable.

Release DATE:2021-06-23

Thermite welding is a method of combining metals by heating the superheated molten metal produced by the exothermic reaction between metal oxide and metal aluminum.

Product type: Ignition gun

Product Introduction:

Thermite welding is a method of combining metals by heating the superheated molten metal produced by the exothermic reaction between metal oxide and metal aluminum.

The first commercial use of this welding process dates back to the late 19th century in Germany, when aluminum was used to reduce iron oxide to make castings and repair broken castings.

Later, this process was gradually popularized, and the connection of copper busbars between rails,

Power grounding systems and cathodic protection.

The welding process simple operation, does not require an external power source and heat source, and the welding of low cost, stable and reliable quality, very suitable for field welding

operation of cable and other metal components, this manual involves the product is suitable for the cathodic protection system installation in the process of copper core cable and

connection of steel structure welding or copper cable.

The characteristics and advantages of thermite welding:

The current closure of the welding point is equal to that of the wire;

The solder joint is permanent and will not cause high resistance due to loosening or corrosion.

The solder joints resemble copper but are stronger than copper itself and are not affected by corrosive products;

The solder joints can withstand repeated large surge current (fault) without degradation;

The welding operation method is simple and easy to use.

The equipment is light and easy to carry;

When welding, no external power or heat source is needed;

The quality of welding can be verified from the appearance;

Can be used for welding copper, copper alloy, copper plated steel, all kinds of alloy steel including stainless steel and high resistance heating heat source material.

客服QQ

客服QQ